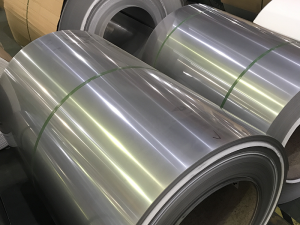

410S Stainless Steel Coil

Katerangan

spésifikasi:

1. Standar: ASTM A240, JIS G4304, EN10088

2. Kelas: 200seri&300seri&400seri

3. Kandel: 0.03mm - 6.0mm

4. rubak: 8mm-600mm

5. Panjang: sakumaha pamundut konsumén '

6. Surface: 2D,2B, BA, Eunteung réngsé, N04, Garis Rambut, Matt finish, 6K, 8K

7.Technology: tiis digambar / tiis digulung / panas digulung

Bahan:

| Tipe | Kelas | Kelas | Komponén Kimia% | ||||||||||

| C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Lain | |||

| Austenitik | 201 | SUS201 | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50–7.50 | ≤0,060 | ≤0,030 | - | ≤1.00 | - | ≤0.25 | - |

| 202 | SUS202 | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0,060 | ≤0,030 | ≤1.00 | - | ≤0.25 | - | ||

| 301 | 1.4310 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | ≤0.10 | - | |

| 304 | 1.4301 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304L | 1.4307 | ≤0,030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 304H | 1.4948 | 0.04-0.10 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309 | 1.4828 | ≤0.20 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 309S | * | ≤0.08 | 22.00-24.00 | 12.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 310 | 1.4842 | ≤0.25 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 310S | * | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1,50 | - | - | - | |

| 314 | 1.4841 | ≤0.25 | 23.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | 1.50-3.00 | - | - | - | |

| 316 | 1.4401 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316L | 1.4404 | ≤0,030 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | - | - | |

| 316Ti | 1.4571 | ≤0.08 | 16.00-18.00 | 10.00-14.00 | ≤2.00 | ≤0,045 | ≤0,030 | 2.00-3.00 | ≤1.00 | - | 0.1 | Ti5(C+N)~0,70 | |

| 317 | * | ≤0.08 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 317L | 1.4438 | ≤0.03 | 18.00-20.00 | 11.00-15.00 | ≤2.00 | ≤0,045 | ≤0,030 | 3.00-4.00 | ≤1.00 | - | 0.1 | - | |

| 321 | 1.4541 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0,70 | |

| 321H | * | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Ti5(C+N)~0,70 | |

| 347 | 1.4550 | ≤0.08 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| 347H | 1.494 | 0.04-0.10 | 17.00-19.00 | 9.00-12.00 | ≤2.00 | ≤0,045 | ≤0,030 | - | ≤1.00 | - | - | Nb≥10*C%-1.10 | |

| Duplex | 2205 | S32205 | ≤0.03 | 22.0-23.0 | 4.5-6.5 | ≤2.00 | ≤0,030 | ≤0,020 | 3.0-3.5 | ≤1.00 | - | 0.14-0.20 | |

| 2507 | S32750 | ≤0.03 | 24.0-26.0 | 6.0-8.0 | ≤1.20 | ≤0,035 | ≤0,020 | 3.0-5.0 | ≤0.80 | 0.5 | 0.24-0.32 | ||

| Ferrite | 409 | S40900 | ≤0.03 | 10.50-11.70 | 0.5 | ≤1.00 | ≤0,040 | ≤0,020 | - | ≤1.00 | - | ≤0,030 | Ti6(C+N)~0.50 Nb:0.17 |

| 430 | 1Cr17 | ≤0.12 | 16.00-18.00 | - | ≤1.0 | ≤0,040 | ≤0,030 | - | ≤1.0 | - | - | - | |

| 444 | S44400 | ≤0,025 | 17.50-19.50 | 1 | ≤1.00 | ≤0,040 | ≤0,030 | 1.75-2.5 | ≤1.00 | - | 0.035 | Ti+Nb:0.2+4(C+N)~0.80 | |

| Martensit | 410 | 1Cr13 | 0.08-0.15 | 11.50-13.50 | 0.75 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - |

| 410S | * | ≤0,080 | 11.50-13.50 | 0.6 | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 420 | 2Cr13 | ≥0.15 | 12.00-14.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | - | ≤1.00 | ≤0,040 | ≤0,030 | - | ≤1.00 | - | - | - | |

| PH | 630 | 17-4PH | ≤0.07 | 15.00-17.50 | 3.00-5.00 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | 3.00-5.00 | - | Nb 0.15-0.45 |

| 631 | 17-7PH | ≤0.09 | 16.00-18.00 | 6.50-7.50 | ≤1.00 | ≤0,035 | ≤0,030 | - | ≤1.00 | ≤0,50 | - | Al 0,75-1,50 | |

| 632 | 15-5PH | ≤0.09 | 14.00-16.00 | 3.50-5.50 | ≤1.00 | ≤0,040 | ≤0,030 | 2.00-3.00 | ≤1.00 | 2.5-4.5 | - | Al 0,75-1,50 | |

Inpo dasar

410s Stainless Steel Coil, kalayan résistansi korosi anu hadé sareng machinability, éta mangrupikeun baja tujuan umum sareng baja alat motong.410S mangrupakeun jenis baja nu bisa ningkatkeun résistansi korosi na formability of 410 steel.410S mangrupakeun baja kakuatan tinggi nu salajengna bisa ngaronjatkeun daya tahan korosi tina 410 steel.Hal ieu dipaké pikeun wilah turbin jeung bagian suhu luhur.

• spésifikasi: AISI 410s, ASTM 410s

• rengse: permukaan Ba, beungeut 2b, No.1 (kulit bodas), beungeut 2D, No.4 (frosted), HL (gambar kawat), beungeut 8K boga kualitas permukaan alus teuing

• tolerances Mill on ketebalan & flatness applies.Call JM Steel lamun perlu ukuran husus atawa arah sisikian.

410S téhnologi machining ciri

1D -- Beungeutna ngagaduhan bentuk granular anu teu kontinyu, ogé katelah permukaan kabut.

téhnologi processing: rolling panas + annealing shot peening pickling + tiis rolling + annealing pickling.

2D - Warna bodas rada pérak.

téhnologi processing: rolling panas + annealing shot peening pickling + tiis rolling + annealing pickling.

2B -- bodas pérak kalayan gloss sareng kerata anu langkung saé tibatan permukaan 2D.

Téknologi ngolah: rolling panas + annealing shot peening pickling + tiis rolling + annealing pickling + quenching na tempering rolling.

Ba - gloss permukaan Alus, reflectivity tinggi, kawas beungeut eunteung.

Téknologi ngolah: rolling panas + annealing shot peening pickling + tiis rolling + annealing pickling + permukaan polishing + quenching na tempering rolling.

No.3 -- gloss alus, permukaan sisikian kasar.

Téknologi pangolahan: polishing sareng tempering rolling pikeun 2D atanapi 2B kalayan 100 ~ 120 bahan abrasive (JIS R6002).

No.4 - gloss alus, garis halus dina beungeut cai.

Prosés ngolah: polishing na tempering rolling pikeun 2D atanapi 2B kalawan 150 ~ 180 bahan abrasive (JIS R6002).

HL -- kulawu pérak kalawan corétan bulu.

Téknologi pangolahan: Produk 2D atanapi produk 2B kalayan granularitas bahan abrasive anu cocog pikeun ngagosok permukaan nyaéta sisikian abrasive kontinyu.

MIRRO -- Specular.

Téknologi pangolahan: produk 2D atanapi produk 2B kalayan granularitas anu pas tina grinding bahan grinding sareng polishing kana pangaruh eunteung.